Portable Wash Racks — Hydropad Systems

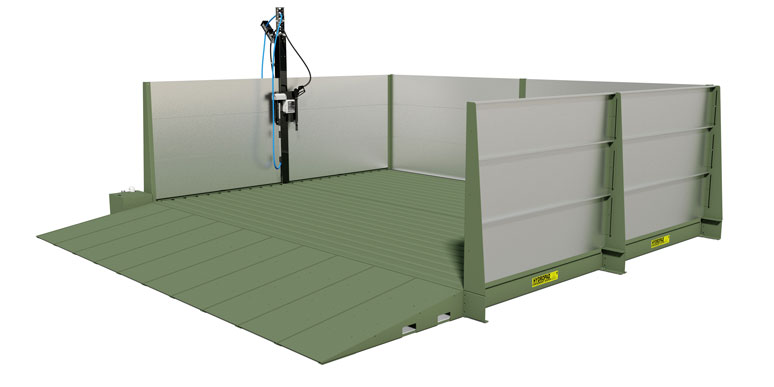

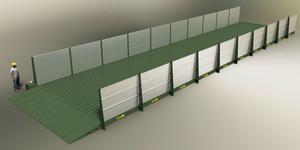

Hydropad above-ground steel wash rack systems provide a reliable solution for capturing wash water and managing waste during cleaning operations. These modular, portable systems are designed to help you centralize wash activities, protect the environment, and reduce operational costs.

Key Benefits of Hydropad Systems

- Localized Wash Area: Keep all wash operations confined to a designated space.

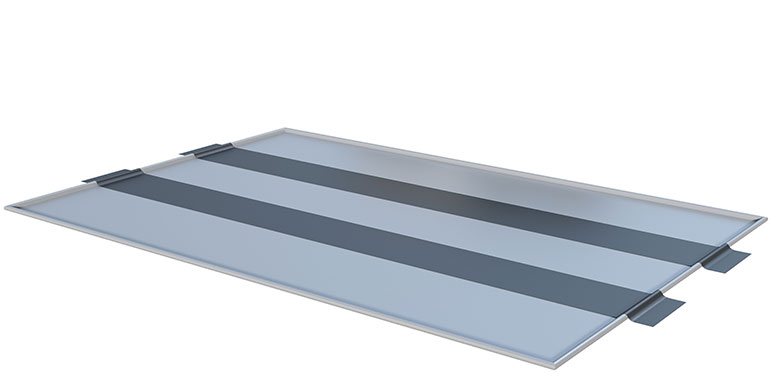

- Efficient Water Capture: Collect wash water and solid waste for proper disposal or recycling.

- Separation Technology: Effectively separate fluids from solids during the wash process.

- Environmental Compliance: Support EPA compliance with responsible wastewater management.

- Water Conservation: Reuse water where applicable to lower consumption and discharge expenses.

- Flexible Deployment: Quick to install, easy to relocate as your needs evolve.

Why Thousands Trust Hydropad Every Day

- Exceptional Durability: Hydropads outperform concrete in longevity and toughness.

- Safety-Focused Design: Integrated Safety Rail System includes a non-skid walking surface.

- Patented Side Gutter: Simplifies water and solid waste removal with easy cleanup.

- Unmatched Strength: Built to be the most rugged and resilient portable wash pad available.

- Splash Control Options: Optional galvanized steel sidewalls help contain overspray and reduce mess.

Hydropad systems are available in a wide range of sizes and configurations to meet your specific washing requirements—whether for vehicles, equipment, or industrial parts.