Screen Reclaiming Systems

Cost-Effective | Proven Performance

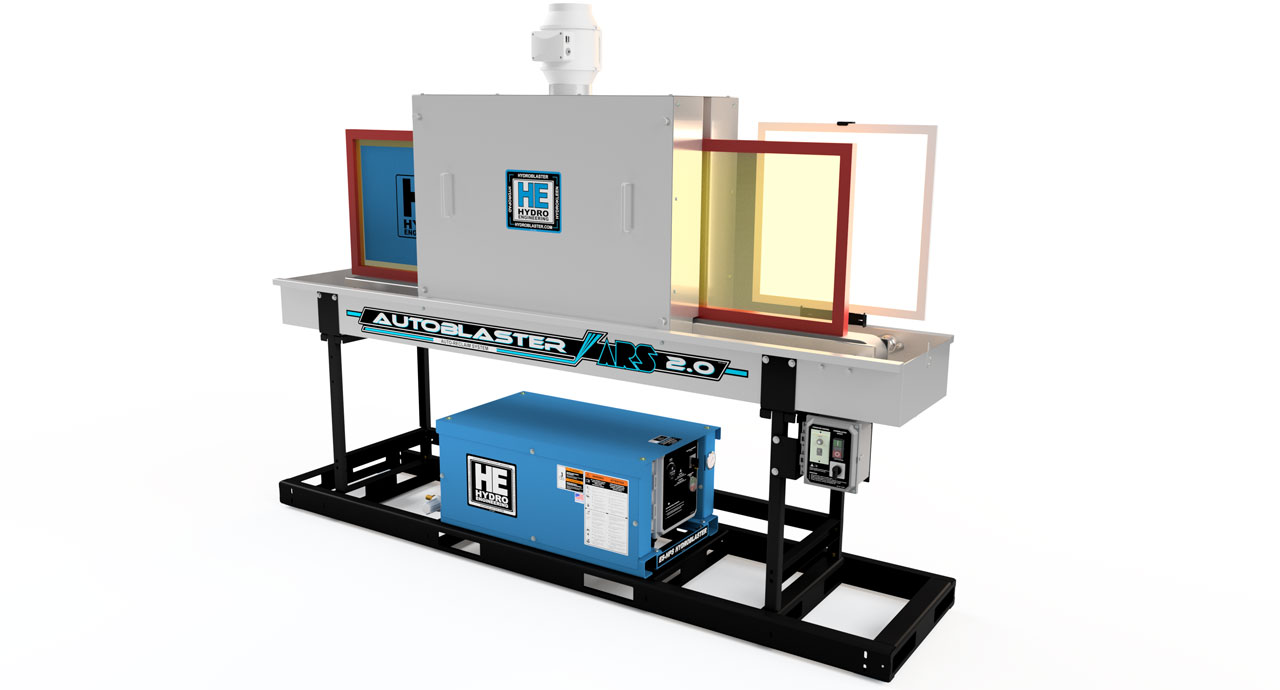

Reclaim Screens Faster with the ARS™ System

Hydro Engineering, Inc. revolutionized the screen printing industry in 1980 with the introduction of the Hydroblaster®—a 3,000 PSI high-pressure washer that could effectively remove emulsion without chemicals and without damaging the screen mesh.

Today, our Automatic Reclaiming System (ARS™) builds on that legacy by offering unmatched simplicity, speed, and cost-efficiency in screen reclaiming.

Reduce Chemicals, Reduce Waste

High-pressure, chemical-free reclaiming delivers more than just superior screen cleaning:

- Ink and emulsion are removed as solids, not sludge

- Solids are easily filtered out using mechanical filtration

- Clarified water is safely discharged to sanitary sewer or treated for recycling

- Ideal for facilities that cannot connect to city sewer systems

Our patented process, first introduced in 1989, remains the gold standard for sustainable screen reclaiming.

Proven by EPA Research

In 1994, Hydro Engineering, Inc.'s reclaiming method was featured in a cooperative study by the U.S. Environmental Protection Agency (EPA) and the Printing Association Nationwide. The findings were clear:

- Lower environmental risk

- Lower operating cost

- Superior reclaiming performance

Integrated Systems Built for Printers

We offer complete reclaiming solutions engineered specifically for screen printers:

- Hydroblaster® pressure washers – Chemical-free cleaning at 3,000 PSI

- Hydrokleen® filtration systems – Treat and recycle wash water or discharge it safely

- Hydrobooth® washout booths – Capture and contain contaminants during washout

These systems are ideal for:

- Print shops with no access to city sewer

- Operations aiming to reduce chemical usage and disposal costs

- Businesses needing compliance with wastewater regulations

Upgrade Your Screen Reclaiming Process

Whether you're starting fresh or upgrading an existing setup, Hydro Engineering, Inc. delivers trusted, field-tested solutions backed by over 40 years of expertise. Our equipment is built for durability, efficiency, and long-term cost savings.

Jump to Products:

- Hydroblaster Pressure Washers

- Hydrobooth Screen Washout Booths

- ECIN Screen Washout Booths

- Hydrokleen Water Filtration

- Solvent Recycling Tank

- Automatic Screen Reclaiming Systems