HE-AUWS/W Automatic Undercarriage & Wheel Wash System

Heavy-Duty Cleaning Power for Industrial & Job Site Applications

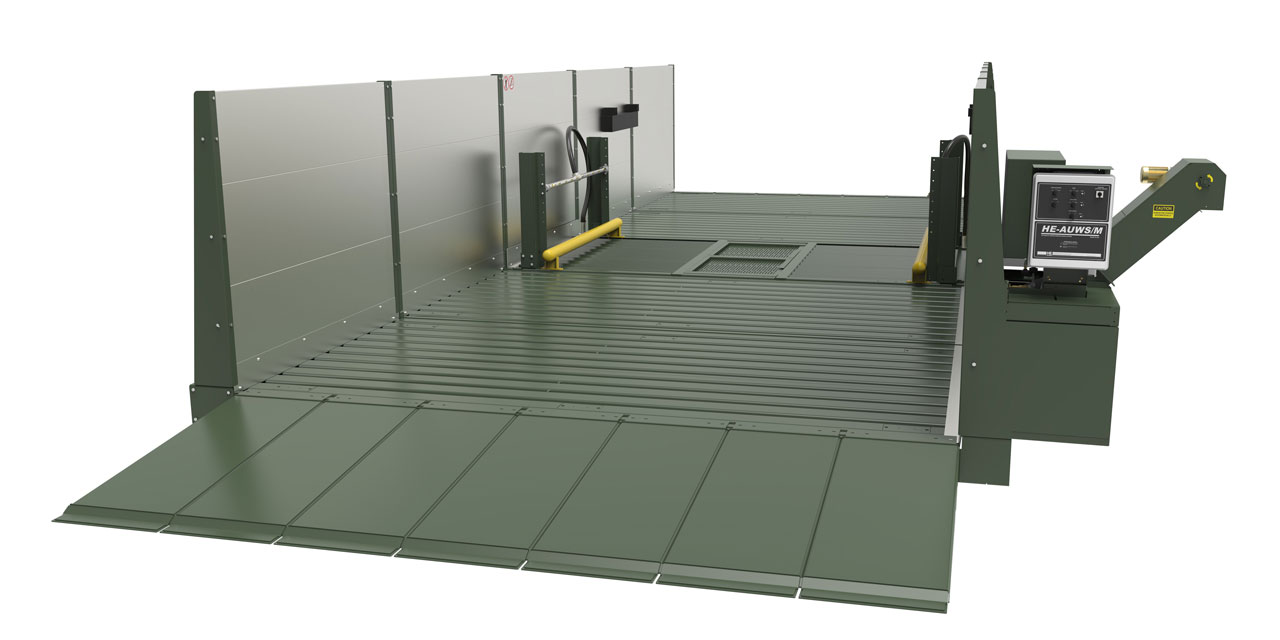

Model HE-AUWS/W (15' Track Width)

Keep mud, dirt, and debris where it belongs—off your roads and out of your facility. The HE-AUWS/W Automatic Undercarriage and Wheel Wash System is a rugged, self-cleaning solution designed to remove heavy soil loads from the undercarriage and sides of vehicles and machinery as they exit job sites or industrial zones.

Fully Automatic, Sensor-Activated Operation

This drive-over wash system features:

- Automated sensors that detect approaching vehicles

- Hands-free activation and timed cycles

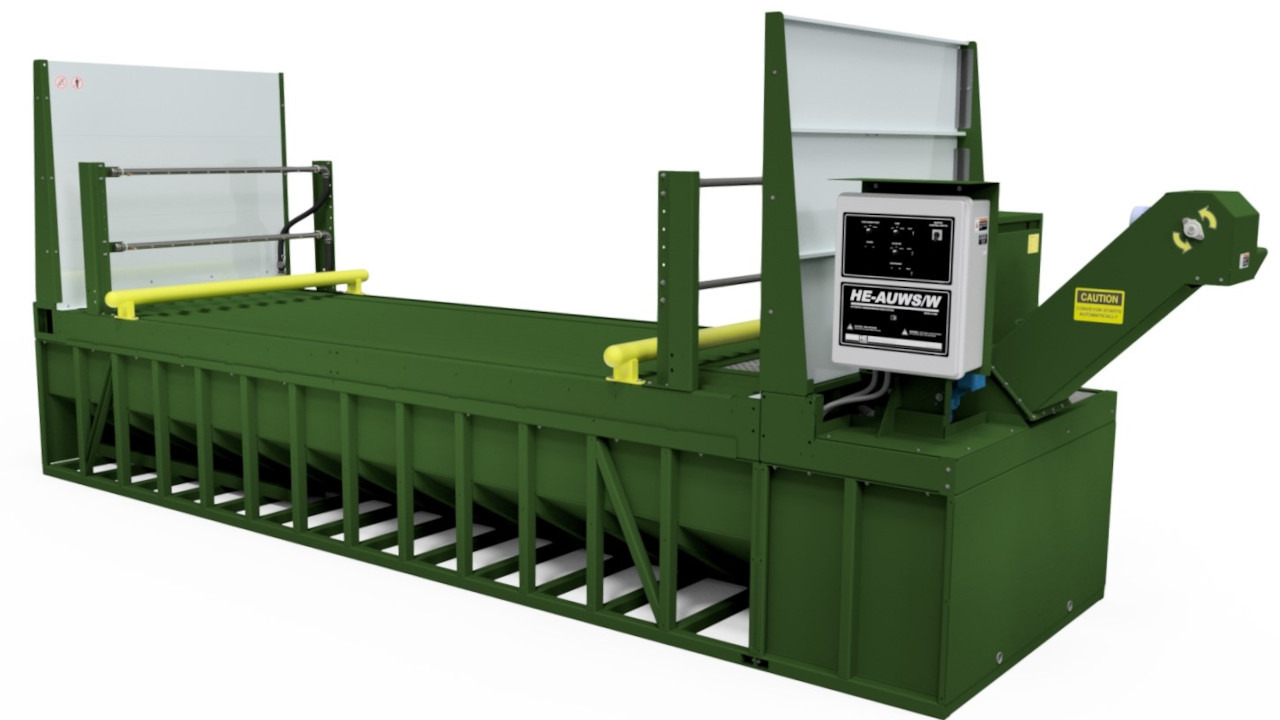

- Self-cleaning grates and internal conveyor system to manage heavy solids

It’s built for unattended, high-volume operation, making it ideal for construction sites, mines, and large-scale fleet yards.

Built for Track-Out Control & Job Site Compliance

Install the HE-AUWS/W at vehicle and equipment exits to eliminate track-out and support environmental compliance. The grated surface allows dirt and debris to fall through, where it is collected and conveyed away by an integral drag conveyor.

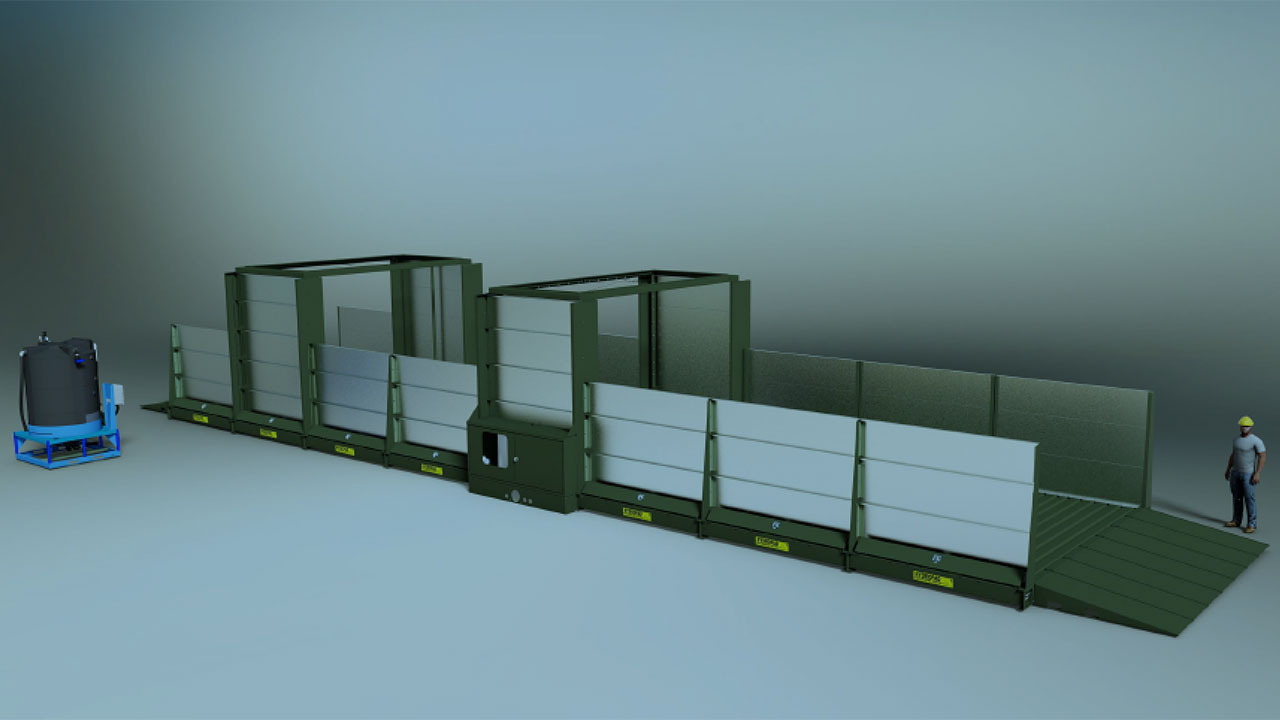

Seamless Wash Rack Integration

For complete system functionality, the HE-AUWS/W can be integrated with Hydropad® above-ground wash rack platforms, creating a modular and scalable wash environment without the need for in-ground construction.

Optional 360° Wash Arch – Full Vehicle Coverage

Upgrade with the optional 360° overhead arch for full top-to-bottom wash capability—perfect for vehicles requiring complete decontamination.

Key Features:

- 15' wide track for large vehicle compatibility

- Handles very heavy soil and mud loads

- Recycles wash water for continuous reuse

- Self-cleaning design with automatic solids removal

- Compatible with Hydropad wash pads for full system integration

- Optional 360° wash arch for full vehicle coverage