Filtration For Machine Tool Coolant Cleaning

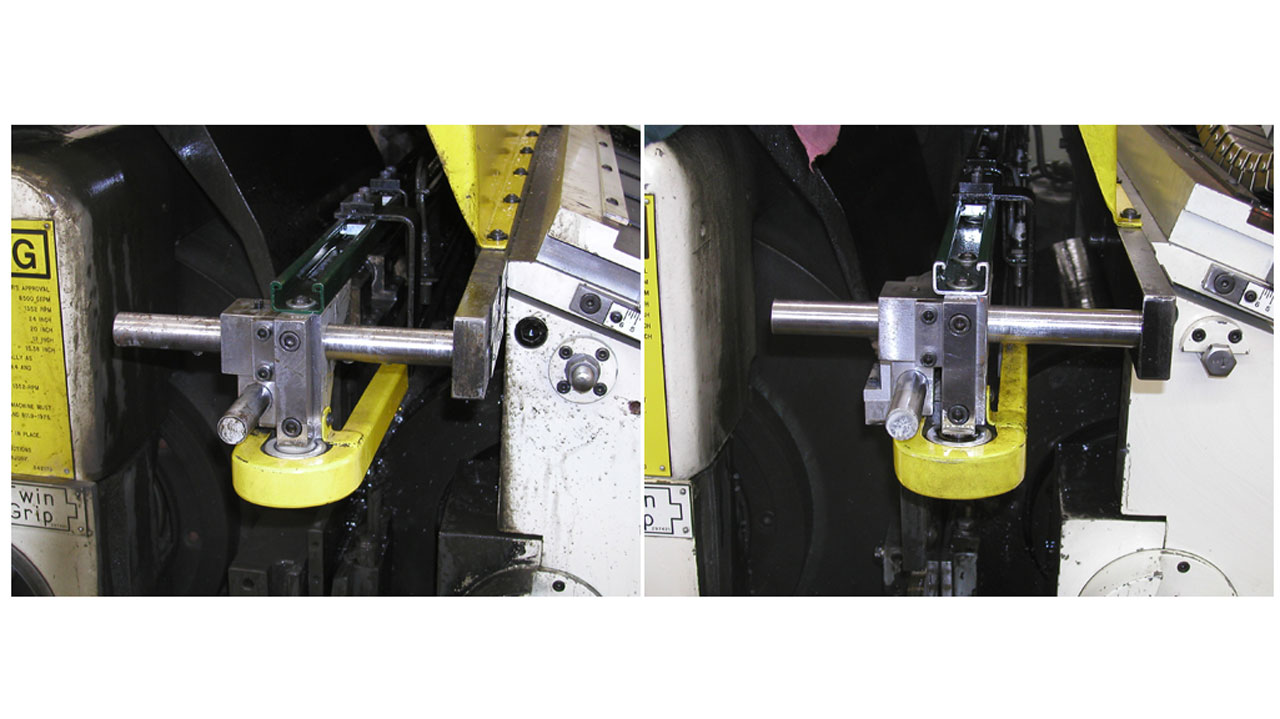

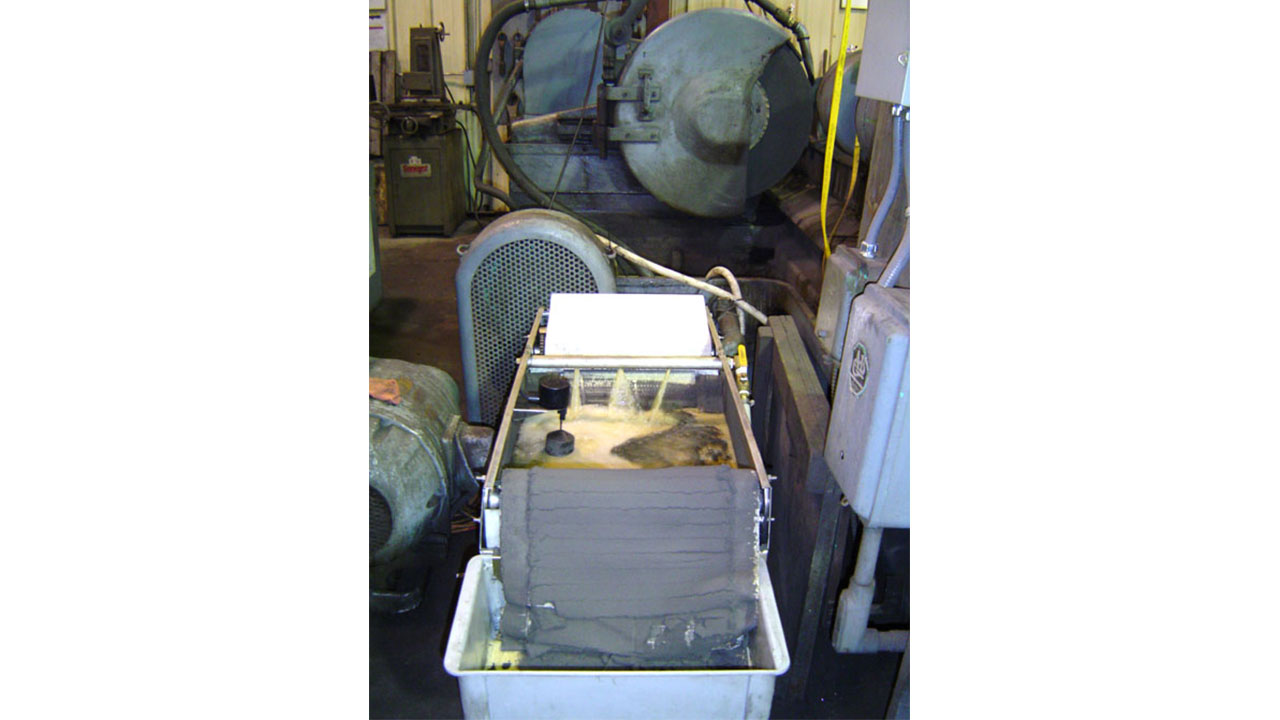

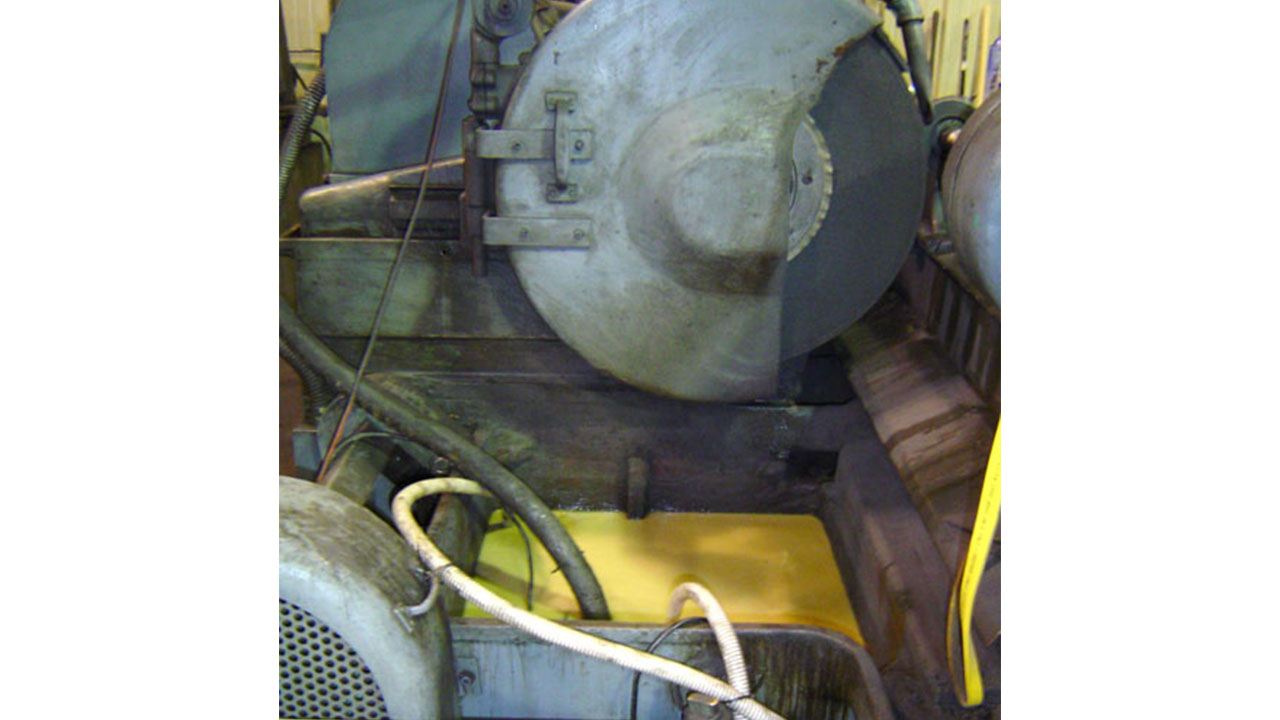

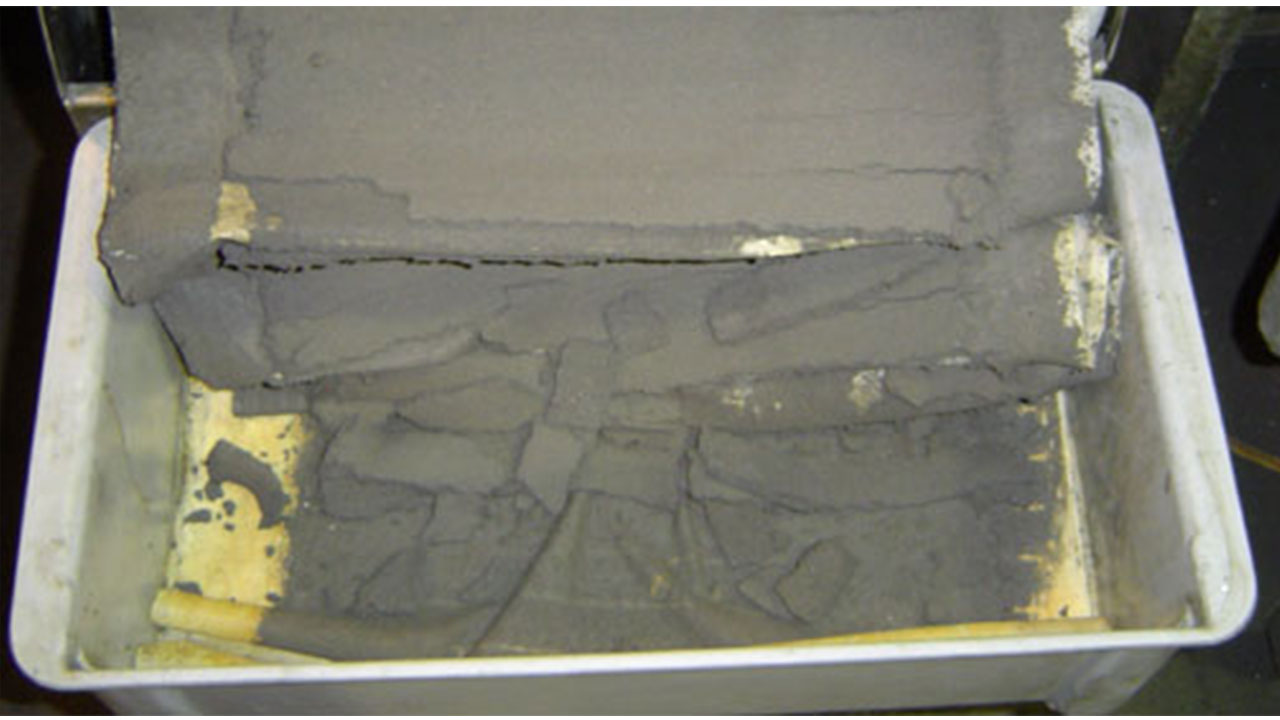

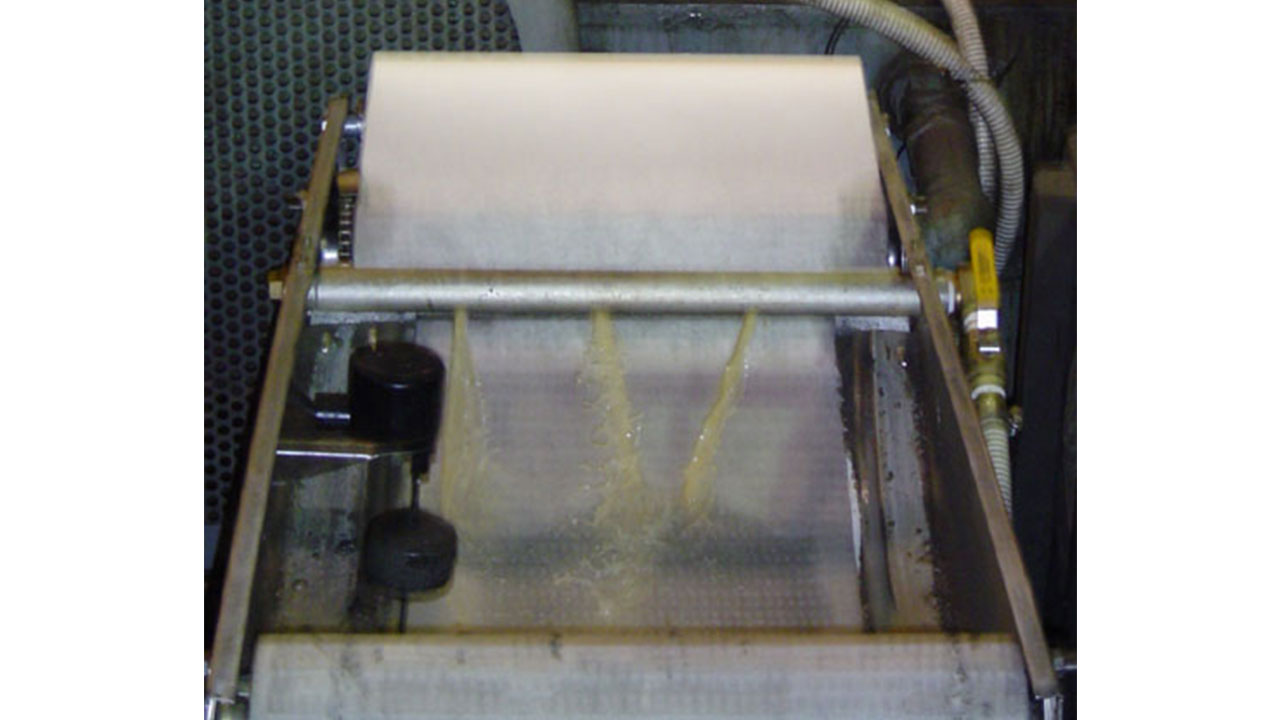

The CMAFU-2 filtration unit will filter solids from coolant in all types of cutting and grinding machines. Coolant is delivered to the CMAFU-2 by a pump and agitator installed in machine tool sump. The CMAFU-2 is typically provided with 100 yard rolls of 5 microns nominal filter paper although filter paper with pore sizes between 1 and 70 micron ratings are available. Paper is automatically replenished as necessary and there are no cartridges to change. Filtered coolant is pumped back to machine tool sump for reuse.

When using water based coolant add Hydro Biodigesters and a small programmable dosing system (PN: 3CO942) at each machine to control organics and bacteria. Biodigesters eliminate tramp oil and organics that support naturally occurring bacteria that not only create unpleasant odors but can also foul pumps and lines. Hydro Biodigesters eliminate the need for disinfectants that are irritating to skin and difficult for personnel to handle. This is a simple low maintenance solution.

Filtering coolant to remove solids and treating coolant to remove tramp oil saves money:

- Coolant life is extended which reduces purchase and disposal costs dramatically

- Wear and tear to machinery will decrease

- Cutting tools will last longer

- Product quality is improved

- Disinfectants and associated skin irritation are eliminated

- One CMAFU-2 can be rolled from machine to machine. Schedule coolant cleaning periodically on every cutting or grinding machine in your shop.